Simple Two-Point Seat Belt

Send Inquiry

Product Features

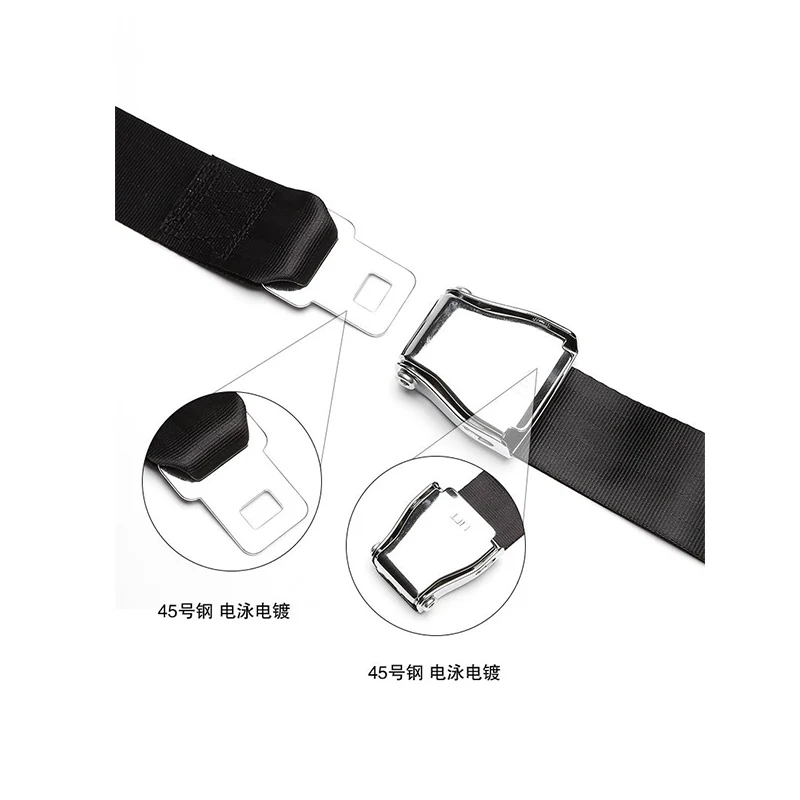

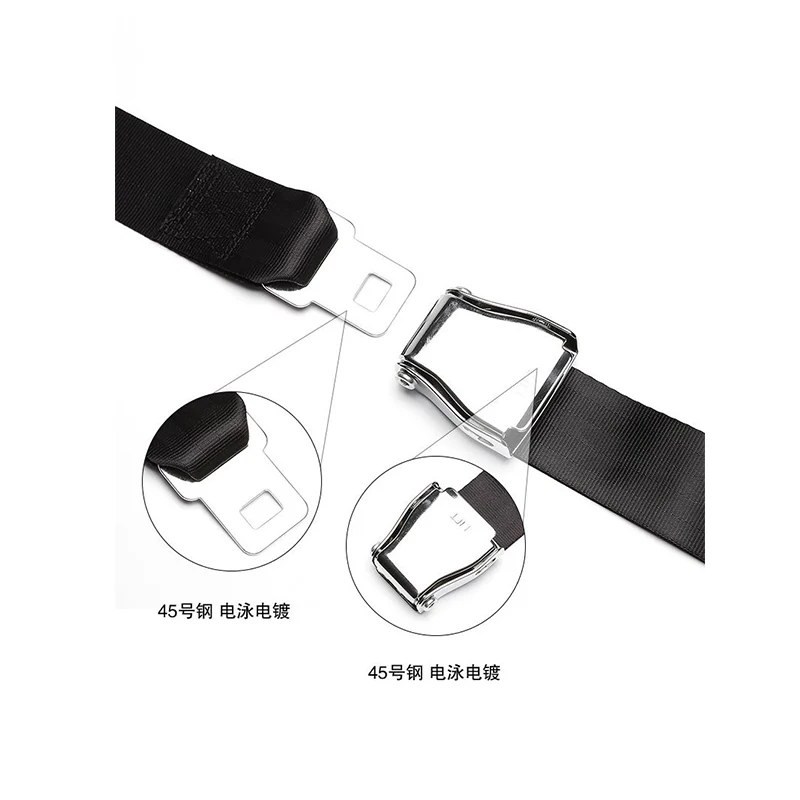

The metal components of Chuanghecheng high quality Simple Two-Point Seat Belt undergo surface treatment processes such as grinding and electrophoresis.

Made of high-strength nylon, it has undergone rigorous testing, achieving a static tensile strength exceeding 20,000 Newtons. This means the product provides reliable protection in emergency situations.

One particularly noteworthy feature is the design of our buckle. Each buckle has undergone tens of thousands of fatigue tests; this means that even with daily use and prolonged use, it will maintain its locking function reliably.

The biggest advantage of our Simple Two-Point Seat Belt is its exceptional value. It's affordable yet maintains high quality. Furthermore, it handles various complex and harsh environments with ease, working stably in extreme heat, cold, humidity, and dryness.

We used an automatic pattern sewing machine for sewing. This machine ensures that the stitching of each seatbelt is very consistent and aesthetically pleasing. Every stitch and every thread is neat and tidy, making the seatbelt not only practical but also very exquisite.

Production Status

The company has 60 employees, including 5 technical experts and 90 experienced production line workers.

Our daily production capacity is very high, producing 3,000 three-point seat belts and 2,000 two-point seat belts per day. Therefore, whether you need a Bulk Simple Two-Point Seat Belt or a custom order, we can guarantee efficient delivery.

Parameter

|

Core components |

Process and Standards |

|

Metal components |

After fine grinding and electrophoresis treatment, the surface is smooth and has strong corrosion and rust resistance. |

|

Safety webbing |

Made of high-strength nylon, with a static tensile strength > 20,000 Newtons. |

|

Snap fasteners |

Passes at least 10,000 fatigue durability tests; smooth opening and closing; long service life. |

|

Sewing process |

The automatic pattern sewing machine produces even and consistent stitches, resulting in a sturdy and aesthetically pleasing finish. |